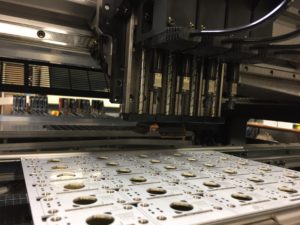

We currently use an Ipulse M20 CPC rated at 19,000cph placing components from 01005 to 120mm x 90mm inc BGA’s and all precisely placed components. We also have a Siemens MS128, generally used for very low volumes and prototypes.

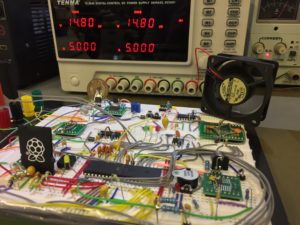

Prototypes

Quick turnaround prototypes, followed by assistance to get your product into full production. We can carry out any modifications following manufacture of prototypes. We are able to assist or design out any issues found at the prototype stage.

Design

In House design engineers will work with yourself and our other partners to take your idea right through to full production. Our engineers will closely liaise with the customer and any other engineers involved to develop a product specification and take that product right through the design stage. Our engineers are at hand to discuss the project at any time, you will find our engineers friendly and flexible, so if you have any concerns or need to make a change to specification, do not worry, don’t hesitate to get in touch directly. We are happy to design and develop in a step by step process to suit the client, therefore, helping the client achieve there goals, when sometimes funding and timescales are a strain. During the design process, careful thought will be given to the design to aid simple, trouble free production and provide a reliable and high quality, cost effective end solution.

Rework

Skilled, experienced re-work staff can modify, repair or replace most components. So whether you decide after build changes need to be made or you have a batch of boards that have been incorrectly manufactured we are able to help.

Conventional

We currently are running a Blundell CMS400D with a lead free solder alloy. The CMS400D is one of the most popular and reliable wave solder machines on the market. The alloy used is the licenced, SN100C. Various spray fluxes can be used depending on the customers preference. We employ a wealth of experience in our operators, so you can rest assured that all hand assembly is carried out with high quality and efficiency in mind.

Mechanical electronic assembly

Mechanical electronic assembly

We have a small work shop for low volume mechanical work, this always comes in handy when a customer needs first off boxes for prototypes, etc.

Full box build and test

We are able to take mechanical drawings and produce box/enclosures for your product, we would produce any low quantities in-house, for larger volumes, we may find it more cost effective to use our partners, who we have a long standing relationship with. We will test your product to a provided specification, or if required, with the help of our engineers we can devise a spec and even create a bespoke test jig with or without the guidance of the customer.

As previously mentioned our wave solder machine is SN100C (lead free), however we still run a leaded process through SMT, and then use hand assembly for the conventional soldering.

We Also Provide Procurement Services click here