Welcome to Dantom Production Solutions

Established in 1997, we have since prided ourselves on working with some of the leading OEM’s and contract manufacturers in the country, as well as many others from across the globe. To this day, we remain in collaboration with some of our first customers; relationships that were forged when our company was founded.

- Services

- SMT

- Wave Solder

- Inspection

- Through Hole Assembly

- PCB Cleaning

- Mechanical Assembly

- Procurement

- Design and Development

– Dantom operates 2 SMT lines, both with fully automatic screen printers, inline reflow ovens and mid-point inspection.

– Although on separate lines, both machines can be programmed and optimised to run large setup boards in unity, or run completely independently to give Dantom and our customers flexibility in production planning.

– We pride ourselves on quick turn prototypes, no matter how large or small. We are happy to receive free issue PCBs and material or offer the full procurement service.

– Of course, we are very competitive when it comes to low-to-medium level production, which we would class as 250,000 placements/day.

CMS 400D

– Dantom uses a totally lead-free process, using SN100C for wave solder.

– Wave solder is preferred to hand soldering, where the design of a PCB and the volume of batch allows.

– All wave soldered PCBs are thoroughly cleaned post assembly.

AOI SYSTEMS

– All PCBs are run through AOI. Customers can rest assured the build is correct and consistent from start to finish.

– At request we can store all images in high resolution to assist customers with queries once a batch has already been shipped. Also where traceability is required this can be an extra, sometimes essential part of the recording.

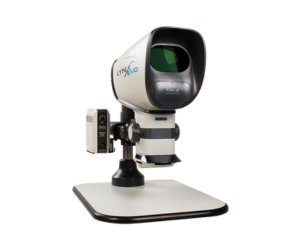

Lynx Evo

– All jobs are also visually inspected during and after assembly, using high quality microscopes from Vision engineering; Lynx Evo being the microscope of choice.

– Trained and skilled assembly operatives produce quality hand soldered/assembled PCBs in an economical, timely fashion, ensuring costing remains competitive where automation is not the preferred technique of assembly.

KED 600

– PCB cleaning is not suitable for every product, due to certain parts being sensitive to the wash. However, the cleaning service is offered as part of Dantom’s standard assembly service.

– Dantom uses Zestron VIGON A201 which is widely used across the electronics industry.

– Solvent dilution and DI water are checked and recorded weekly for customers’ reassurance.

– Dantom has a small model shop where we undertake lower volume machining for box build and other mechanical assemblies.

– Again, we have extensive experience through our staff in various types of box build and mechanical assembly.

– Wiring looms and other wiring assemblies are part of our everyday duties. However, where very complex and specifics are required, we work very closely with specialist partners.

– Dantom employs a team dedicated to procurement and stock handling.

– As a subcontract manufacturer, we allow our customer to dictate how we source and schedule material and then even the finished product.

– Where traceability is a must, this information can be shared with customers via their systems, or we tailor to suit.

– We have a large supplier pool, which we can share where necessary with customers.

– Dantom have a small design team that can help customers take their PCB designs that need a tweak, or brand-new ideas, into full production.

– New projects start with a simple brainstorming meeting, taking your project out of imagination, onto a schematic and into Gerbers ready to make your product a reality.

– As we offer the full turnkey solution in house, there is no need to look elsewhere for prototyping. We can include this as part of the package at the outset if you should so wish.

– Following prototyping, we are then able to offer the full manufacturing service – procurement through to distribution. You will by now have your own key account person(s), so you can relax, safe in the knowledge that your project remains in good hands for its entirety.

Yamaha IPULSE S20

Our Iplulse S20 is a flexible, 6 head, high speed mounter making the machine ideal for both prototyping and rapid production. Able to place the smallest of Passives up to large BGAs or specialist Modules.

KED600

Our KED600 is a high-performance standalone batch cleaner that efficiently cleans PCBs and low standoff components like BGA, QFN, CSP, and BTC. The machine’s two drawer baskets enable maximum throughput, making it perfect for industrial cleaning applications. It is suitable for small and medium PCBA production capacity. The processes of cleaning, rinsing and drying are running automatically inside the chamber. With a suitable fixture, it also can be used for lens and other machinery parts cleaning.

YAMAHA IPULSE M20

Our Iplulse M20 is a flexible, 4 head, high speed mounter making the machine ideal for both prototyping and rapid production. Able to place the smallest of Passives up to large BGAs or specialist Modules.

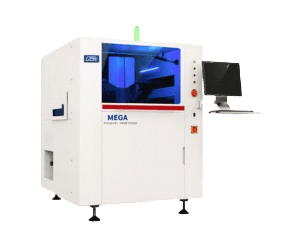

Mega TSE3070T Automatic stencil printer

The TSE3070T fully automatic SMT solder paste stencil printer provides a package of everything that is needed in a fully automatic in-line printer to produce high quality, high precision and high speed solder paste prints.

HTS0601 6 Zone Lead Free Reflow Oven

The HTS0601 reflow oven is the perfect fit for Dantom, with excellent efficiency, we are able to accurately profile the widest variety of PCBAs, fitted with both Edge Pin and Mesh Belt conveyor system for ultimate flexibility.

AOI Scanner Based FA Inspector

The FA-Inspector has two primary modes of operation: Comparator Mode and AOI Mode. Both AOI and Comparator Modes generate comprehensive reports complete with error location marks, fault classifications including the full PCB image or XY layout for easy rework. Reports can be viewed, printed, saved or emailed to customers for rapid prototype review. Defect coverage includes, all SMT and PTH parts down to 01005, part presence/absence verification, part polarity and pin #1 orientation, part position and skew errors, laser marking, wrong part and device differences such as: labels and colour variations.

DEK Horizon

Our Dek Horizion provides Dantom with all the features to give the capability to produce prints at the highest quality, whilst giving us that extra flexibility when manufacturing larger PCBs (620 x 508mm).

Lynx EVO Stereo Microscope

Our Lynx EVO stereo microscope allows inspection, production, reworking, or anything else requiring magnification – it has 3D depth perception and bright, high resolution, high contrast images with magnifications from 2.7x to 240x which make it ideal for a wide range of applications.

Quick Links

Follow Us

Copyright © 2025 Dantom Production Solutions. All rights reserved.